Ukuze uzivumelanise nokunakwa okwandayo kwamazwe ngamazwe ekuvikelweni kwemvelo, i-PCBA yashintsha kusukela ekuholeni kuya ekuholeni inqubo yamahhala, futhi yasebenzisa izinto ezintsha ze-laminate, lezi zinguquko zizobangela izinguquko ze-PCB zemikhiqizo ye-electronic solder ukusebenza okuhlangene.Ngenxa yokuthi amajoyinti e-solder azwela kakhulu ekuhlulekeni kobunzima, kubalulekile ukuqonda izici zobunzima ze-PCB electronics ngaphansi kwezimo ezinzima kakhulu ngokuhlolwa kobunzima.

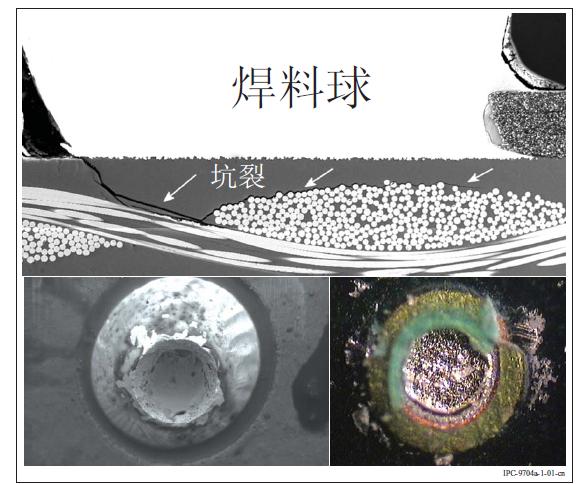

Kuma-alloys ahlukene e-solder, izinhlobo zephakheji, ukwelashwa okungaphezulu noma izinto ze-laminate, ukucindezeleka ngokweqile kungaholela ezindleleni ezihlukahlukene zokwehluleka.Ukwehluleka kufaka phakathi ukuqhekeka kwebhola le-solder, ukulimala kwezintambo, ukwehluleka kokubopha okuhlobene ne-laminate (i-pad skewing) noma ukwehluleka kokuhlangana (i-pad pitting), kanye nokuqhekeka kwe-substrate yephakheji (bona Umfanekiso 1-1).Ukusetshenziswa kokulinganisa kobunzima ukuze kulawulwe ukusonteka kwamabhodi aphrintiwe kubonakale kunenzuzo embonini yezogesi futhi kuthola ukwamukelwa njengendlela yokuhlonza nokwenza ngcono imisebenzi yokukhiqiza.

Ukuhlolwa kobunzima kunikeza ukuhlaziya okuhlosiwe kwezinga lobunzima kanye nesilinganiso sobunzima amaphakheji e-SMT angaphansi kwawo ngesikhathi sokuhlanganiswa kwe-PCBA, ukuhlolwa, nokusebenza, okuhlinzeka indlela yobuningi yokulinganisa kwekhasi lempi le-PCB nokuhlola isilinganiso sengozi.

Umgomo wokulinganisa ubunzima ukuchaza izici zazo zonke izinyathelo zokuhlanganisa ezifaka imithwalo yemishini.

Isikhathi sokuthumela: Apr-19-2024